Standard:

Metal hose design criteria

Wall thickness:

Wall thickness of the hose is decided by the manufacturer considering the flexibility, pressure rating and corrosion requirements. Thick and thin walled hoses have both advantages and disadvantages. Hence, wall thickness of hose shall be selected depending on the application.

Complete application details of hose assembly should be informed to the manufacturer to select suitable wall thickness.

Hose Protection

-

- External protection – heat

Ceramic cloth/sleeve or silica cloth/sleeve are wrapped or inserted over the braided hose to protect the braid from heat and hot particles. These protective materials are suitable for temperature up to 1200 ºC.

-

- External protection – corrosive atmosphere.

Rubber or PVC sleeve protection can be given to hose assemblies to protect it from corrosive atmosphere contaminated with Hydrogen Supplied, Chloride etc.

-

- External protection – mechanical.

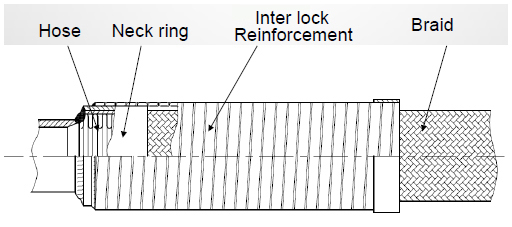

An interlock armor protection can be given to full hose assemblies to protect it from external mechanical damages and abrasion. Some cases, coil spring.

Height and pitch of convolution

Height and pitch of convolution of metallic hose is another design criteria to be considered.

High convolution gives excellent fatigue life but has poor pressure capacity.

A closely pitched hose with normal convolution height can give good cycle life at high pressure. As the wall thickness in this case is less, the corrosion life is less. Suitable combination of pitch, wall thickness and convolution height are selected to suit the application.

Outputs based on User Input

-

Suitable size and length of hose assemblies are suggested based on pressure drop requirement, installation requirement, dynamic properties, etc.

Hose Storage

- Cleaned hoses stored with its ends properly caped / closed.

- Smaller size hoses- up to 80 NB can be coiled with radius not less than the specified bend radius.

- Hoses 100 NB and above shall be stored in straight lengths or with higher bend radius.

- Avoid contact of carbon steel parts with hose during storage.

- Pressure test the hose before use when stored for a long period.

Hose Cleaning

- No internal cleaning is required if the hoses are installed permanently in the plant.

- If flushing of piping is done on any plant with the hosed in installed condition, it is recommended to remove the hoses and clean internally.

- Internal fleshing of hose is done by passing free flow DM water (Chloride content not more than 30 PPM) into the hose.

- If the hose assemblies are used intermittently (in case of corrosive chemicals) , after every usage, they are cleaned, dried and stored properly.